Chips shortage comes the cell phones: this affects us |Digital Trends Spanish

Chips scarcity begins to transform into a major problem.Although it seemed to be a circumscribed issue to the automotive industry, it extends to electronic companies, such as smartphone manufacturers.

At the end of 2020, the German company Volkswagen became the first car manufacturer to recognize that the scarcity of semiconductors had caused delays in its production.Ford and General Motors joined later.

The matter even became one of the first concerns of the president of the United States Joe Biden, who has evaluated the possibility of assigning funds to promote the manufacture of these supplies in the United States.

Why are chips important

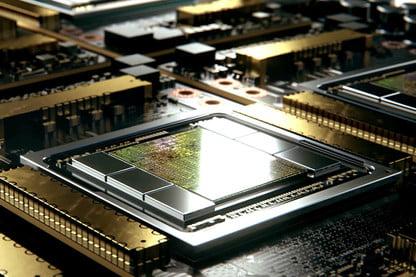

Semiconductors, popularly known as chips, are an essential component for the operation of a wide range of daily products, from cell phones to computers, televisions and latest generation refrigerators.

The semiconductors, also called microchips, are devices manufactured based on silicon and are composed of millions of transistors, which act as small “switches” to control the movement of electrons.

The disposal of transistors will determine the function of the chip, which can serve to process large amounts of data (the CPU and GPU of the computers) or for their storage (hard drives or RAM), for example.

The origin of chips scarcity

Chips scarcity began after coronavirus pandemic.With a significant percentage of the population confined in their homes, the world demand for cars slowed down.

This caused automobile companies to reduce production, as well as purchases of supplies necessary for their manufacture, including semiconductors.

How to Print in Black and White on Epson Printers? #MetsatReds #printersupportnumber https://t.CO/ZTPVKLWZQF

— All In One Service Tue Jul 20 09:30:41 +0000 2021

In parallel, the demand for chips shot by companies that make computers and other equipment that allowed employees to work from home.

When cars production was recovered, the automotive industry faced a scarcity of semiconductors.

Analysts estimate that automotive semiconductor supplies could not return to normal during a couple of quarters.

The shortage reaches mobile telephony

Until now, the shortage had focused on chips made of older technology, instead of the most advanced phone processors.

However, a report by the Reuters agency assured that the American manufacturer Qualcomm struggles to respond to the demand for phones and other devices.

Qualcomm chips demand has shot in recent months, as other Android phone manufacturers seek to win customers who leave Huawei.

Qualcomm has had difficulty satisfying this demand superior to that expected, partly due to the shortage of some subcomponents used in their chips.

One of the largest affected is Samsung Electronics, which would be experiencing problems in the production of mid -range and low -end models.

However, other versions cited by Reuters suggest that there would also be problems with the production of state -of -the -art chips, such as Snapdragon 888.

Qualcomm limitations show how problems in an area of the complex chip supply chain - which establish mass production plans with years in advance - can affect others.

"We still have a basically higher demand than the supply," said the incoming executive president of Qualcomm Cristiano Amon during the company's annual meeting.

Chips scarcity, which has caused panic purchases, further reduces capacity and increases even the cheapest components of almost all microchips, experts in the industry said.